Flex Molds

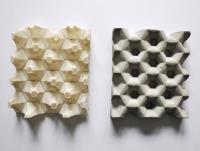

Flex.Molds explores the potential of using flexible plastic in conjunction with standard 3D printing techniques to fabricate 3D printed flexible molds for casting concrete. It poses the question: can 3D printing formwork for concrete alleviate some of the problems associated with traditional casting by reducing fabrication steps and increasing geometric flexibility?

The initial research for Flex.Molds was carried out during an elective offered to undergraduate and graduate students at Kent State University, which subsequently led to design development, data collection and the development of guidelines for architects and fabricators who are interested in exploring this new technique. This paper describes the background research, current state of digitally fabricated molds, 3D printing materials, fabrication and casting processes, typical workflow from design to fabrication, design limitations and opportunities, and conclusions.

Add comment

Log in to post comments